Hidden damage, including corrosion and rust, is a significant vehicle issue in harsh environments. Advanced tools like thermal imaging aid in early detection through hidden damage inspection. Prompt identification enables effective rust prevention, maintaining vehicle longevity and safety. Regular maintenance and prompt dent removal at collision centers are key strategies to protect against corrosion and preserve vehicle condition.

Hidden damage, often concealed by surfaces that appear intact, can be a silent menace, leading to structural integrity issues. This article delves into the critical aspect of hidden damage inspection, focusing on corrosion and rust prevention. We explore the underlying causes and effects of this insidious problem, highlighting advanced techniques for thorough inspection. Furthermore, practical strategies are offered to mitigate corrosion and rust post-inspection, ensuring long-lasting protection for various materials and structures.

- Understanding Hidden Damage: Causes and Effects

- Advanced Techniques for Efficient Inspection

- Strategies to Prevent Corrosion and Rust After Inspection

Understanding Hidden Damage: Causes and Effects

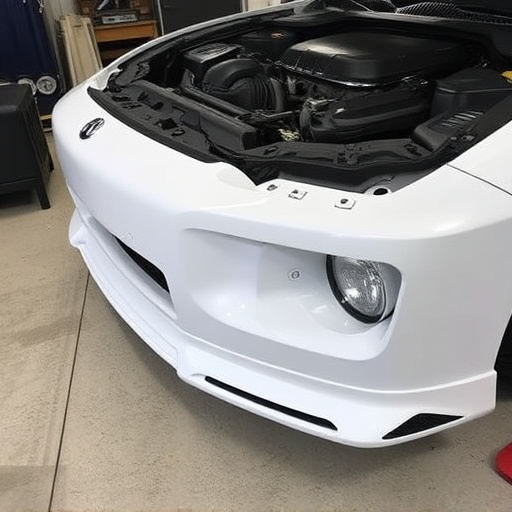

Hidden damage, often invisible to the naked eye, can be a significant concern for structures and materials exposed to harsh environments. In the context of vehicles, this hidden damage manifests as corrosion and rust, which may have subtle beginnings but can lead to severe structural integrity issues over time. Causes vary from minor dents and dings due to everyday use to more substantial impacts from vehicle collisions. These incidents can create crevices and pockets where moisture and oxygen infiltrate, initiating the corrosion process.

The effects of hidden damage are far-reaching. In an auto collision center or auto body shop, experienced technicians employ advanced techniques like hidden damage inspection using specialized tools to detect these early signs of deterioration. Prompt identification is crucial as it enables effective rust prevention strategies, ensuring the longevity and safety of vehicles. Ignoring hidden damage can result in weakened components, compromising both performance and the structural integrity of vehicles during subsequent operations.

Advanced Techniques for Efficient Inspection

In the realm of hidden damage inspection, modern technologies have revolutionized corrosion and rust prevention strategies. Advanced techniques like thermal imaging and ultraviolet (UV) lighting offer a glimpse into the unseen, revealing pitting, peeling paint, and underlying metal imperfections that would otherwise go undetected during a visual inspection. These tools are invaluable assets for auto body shops and classic car restorers, enabling them to perform comprehensive assessments with precision and efficiency.

By employing these innovative methods, professionals can identify even the subtlest signs of corrosion and rust at their nascent stages. This proactive approach is pivotal in averting significant damage down the line, ensuring that vehicles, especially classics, remain in pristine condition. Moreover, the data gleaned from such inspections guides tailored repair strategies, including effective car scratch repair techniques and restoration processes, ultimately contributing to the longevity and aesthetic appeal of every vehicle that passes through an auto body shop.

Strategies to Prevent Corrosion and Rust After Inspection

After a thorough hidden damage inspection, it’s crucial to implement preventive strategies to safeguard against corrosion and rust. One effective approach is regular maintenance, which includes washing and waxing the vehicle to create a protective barrier against moisture and harsh elements. This simple step can significantly delay the onset of corrosion.

Additionally, considering services offered by an auto collision center or collision repair shop for dent removal can improve the overall aesthetics and structural integrity of the car. By promptly addressing any dents or damages, these professionals can prevent further complications that might lead to rust formation over time. Regular checks and timely repairs are key to maintaining a vehicle’s condition and longevity, ensuring it remains free from hidden damage and its associated corrosion risks.

Hidden damage, often obscured by surfaces that appear intact, can be a significant issue for structures and equipment. By employing advanced inspection techniques, professionals can uncover these silent threats, enabling proactive measures to prevent corrosion and rust. Understanding the causes and effects of hidden damage is crucial, as it allows for the implementation of effective strategies to safeguard against future deterioration. With the right tools and expertise, regular hidden damage inspections become a powerful tool in maintaining the longevity and integrity of various assets.