Hidden Damage Inspection is a meticulous process conducted by skilled technicians using advanced tools like 3D scanners, thermal imaging cameras, and magnetic particle inspection (MPI) to uncover critical safety hazards in vehicles beyond surface-level assessments. This comprehensive examination identifies issues such as dents, cracks, rust, or structural damage, ensuring vehicle safety, preventing risks, and facilitating accurate repair by revealing flaws that routine visual inspections might overlook. Regular hidden damage inspections are crucial for maintaining optimal vehicle performance, enhanced safety, and mitigating the risk of catastrophic failures. Modern technologies revolutionize collision repair processes by providing precise and detailed assessments of vehicle condition.

Hidden damage inspection plays a pivotal role in ensuring vehicle safety. This critical process uncovers latent issues often invisible to the naked eye, safeguarding drivers and passengers from potential hazards on the road. By delving into the intricacies of hidden damage, this article aims to illuminate the importance, processes, and technologies involved in enhancing vehicle security. Understanding these elements is key to maintaining a robust safety standard in today’s automotive landscape.

- Understanding Hidden Damage Inspection: Unveiling the Process

- The Impact on Vehicle Safety: Why It Matters

- Technologies and Tools Used in Modern Inspections

Understanding Hidden Damage Inspection: Unveiling the Process

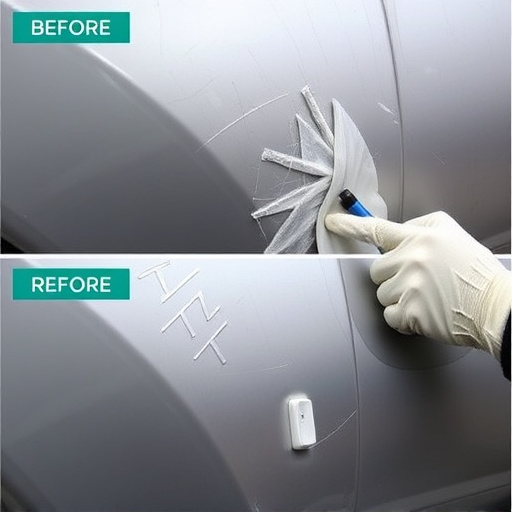

Hidden Damage Inspection is a critical process that goes beyond surface-level assessments to uncover potential safety hazards in vehicles. It involves a meticulous examination of various components, often hidden from immediate view, within and around the car. This includes checking for dents, cracks, rust, or damage to structural elements like frames and suspension systems. Skilled technicians utilize advanced tools and techniques to ensure every nook and cranny is examined, revealing issues that might be overlooked during routine visual inspections.

The process begins with a detailed walk-around, where experts look for any visible signs of damage. This is followed by utilizing specialized equipment such as 3D scanners, thermal imaging cameras, and magnetic particle inspection (MPI) to detect hidden imperfections in the car body shop. For instance, car paint services might reveal underlying issues like poor panel alignment or subpar repairs that could compromise structural integrity during a thorough hidden damage inspection. Effective hidden damage inspection is pivotal in ensuring vehicle safety, identifying potential risks, and facilitating accurate car damage repair when needed.

The Impact on Vehicle Safety: Why It Matters

Hidden damage inspection plays a pivotal role in ensuring vehicle safety, often overlooked but with profound implications. Beyond what meets the eye, vehicles can sustain subtle yet structural damages during accidents or normal wear and tear. These hidden flaws, such as cracked panels, damaged frames, or compromised welds, can compromise the integrity of the vehicle’s structure, posing potential risks to drivers and passengers.

Regular and thorough hidden damage inspections by trained professionals in an automotive body shop are essential. Just as a bumper repair or vehicle body repair addresses visible issues, a comprehensive inspection uncovers latent problems. By identifying these hidden damages early, mechanics can prevent them from escalating, ensuring optimal vehicle performance, enhanced safety features, and minimizing the risk of catastrophic failures.

Technologies and Tools Used in Modern Inspections

Modern hidden damage inspections leverage a range of advanced technologies and tools to ensure comprehensive assessments of vehicle condition. These include high-resolution cameras that capture detailed images from various angles, allowing for a thorough visual examination of hard-to-reach areas. Thermal imaging technology is also employed to detect heat discrepancies, indicative of potential structural or mechanical issues. Additionally, non-destructive testing methods like ultrasound and infrared are utilized to assess internal components without causing further damage.

The integration of these technologies has revolutionized hidden damage inspection processes, enabling auto collision repair specialists to conduct precise vehicle body repairs. By identifying subtle imperfections that might go unnoticed during manual inspections, these tools play a pivotal role in maintaining the structural integrity of car bodywork, thereby enhancing overall vehicle safety.

Hidden damage inspection plays a pivotal role in vehicle safety, ensuring that potential hazards are identified and addressed before they become critical. By delving into this process, we’ve seen how it not only uncovers hidden defects but also significantly enhances overall vehicle safety. Modern inspections leverage advanced technologies and tools to detect even the subtlest damages, making roads safer for drivers and passengers alike. Staying proactive in hidden damage inspection is essential to mitigate risks and maintain a robust safety standard in the automotive industry.